Silicon Carbide vs. Aluminum Oxide Firepolish Comparison Test

Micrographs by Nikki O’Neill

Samples by Tony Smith and Steve Immerman

The purpose of this page is to demonstrate some of the functional differences between the two common sandblaster abrasives. The conclusion of this series of observations is that if you plan to blast and then refire glass, that Aluminum Oxide is a preferable abrasive. It results in a surface that is quite similar to virgin glass.

The summary is that Silicon Carbide is a more aggressive abrasive, and works well for deep blasting. But, when glass blasted with SiC is refired – it traps microscopic bubbles below the surface – resulting in a hazy appearance. The photos below show the evidence for this conclusion.

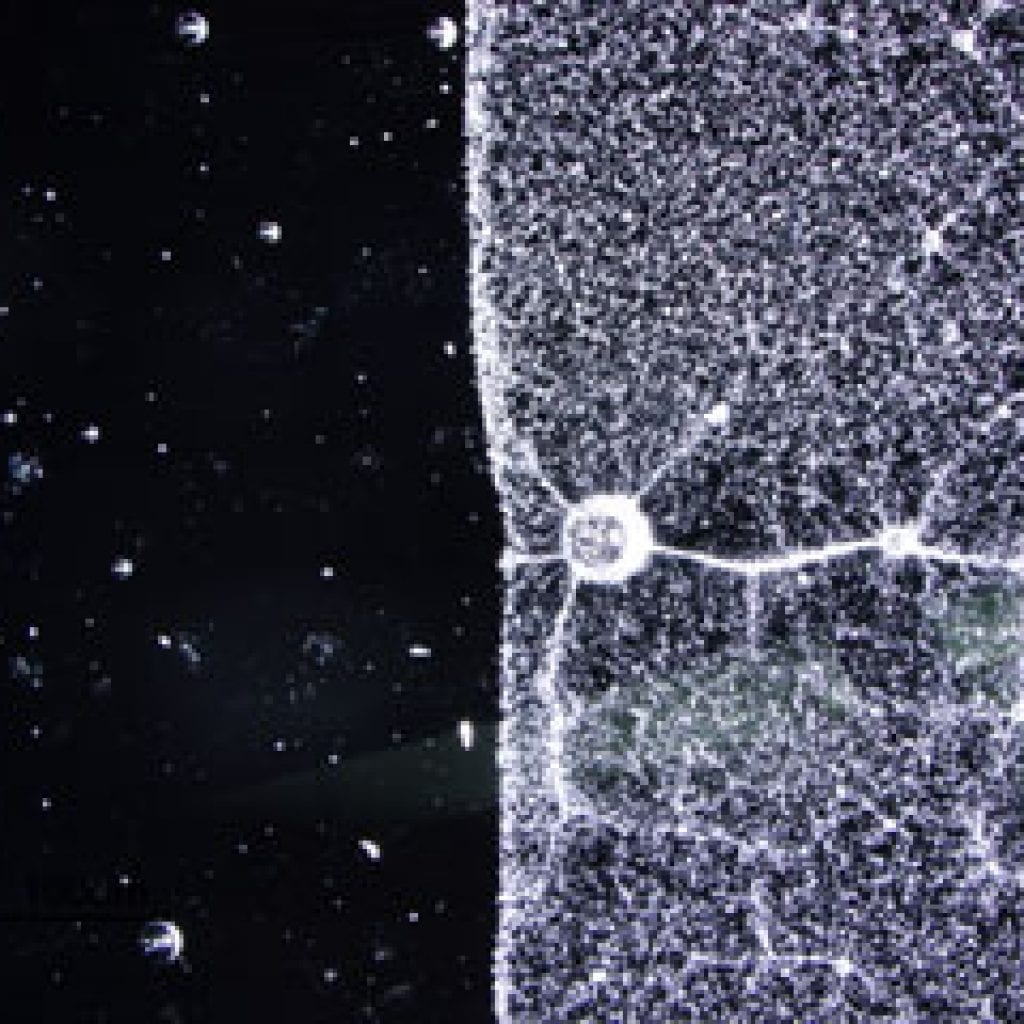

This is a sample of Bullseye clear glass. The left half has not been blasted, the right half has been blasted with 120 grit Silicon Carbide by Tony Smith and then firepolished . I believe that this demonstrates that a glass surface that is blasted with silicon carbide and firepolished, although acceptable to the naked eye, may not end up the same as a “virgin” surface.

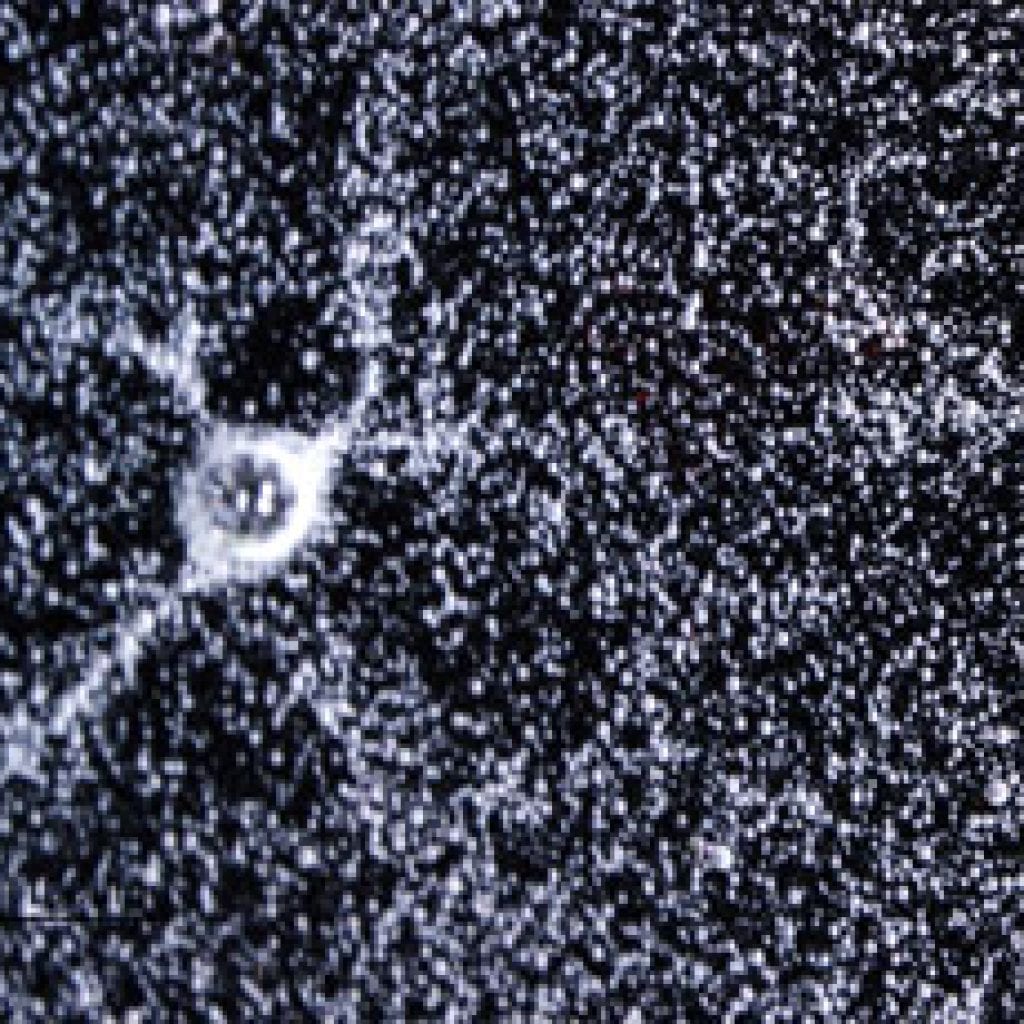

This is a close-up of the above image. Note the bubbles in the side blasted with Silicon Carbide and then firepolished.

This sample was Bullseye black, blasted with 120 grit Aluminum Oxide, 20 psi. Firepolished to 1450 degrees. (White circles are frit place on the surface as identification markers.)

Nikki’s observations:

“There wasn’t much to see. Very few nicks and small fractures.”

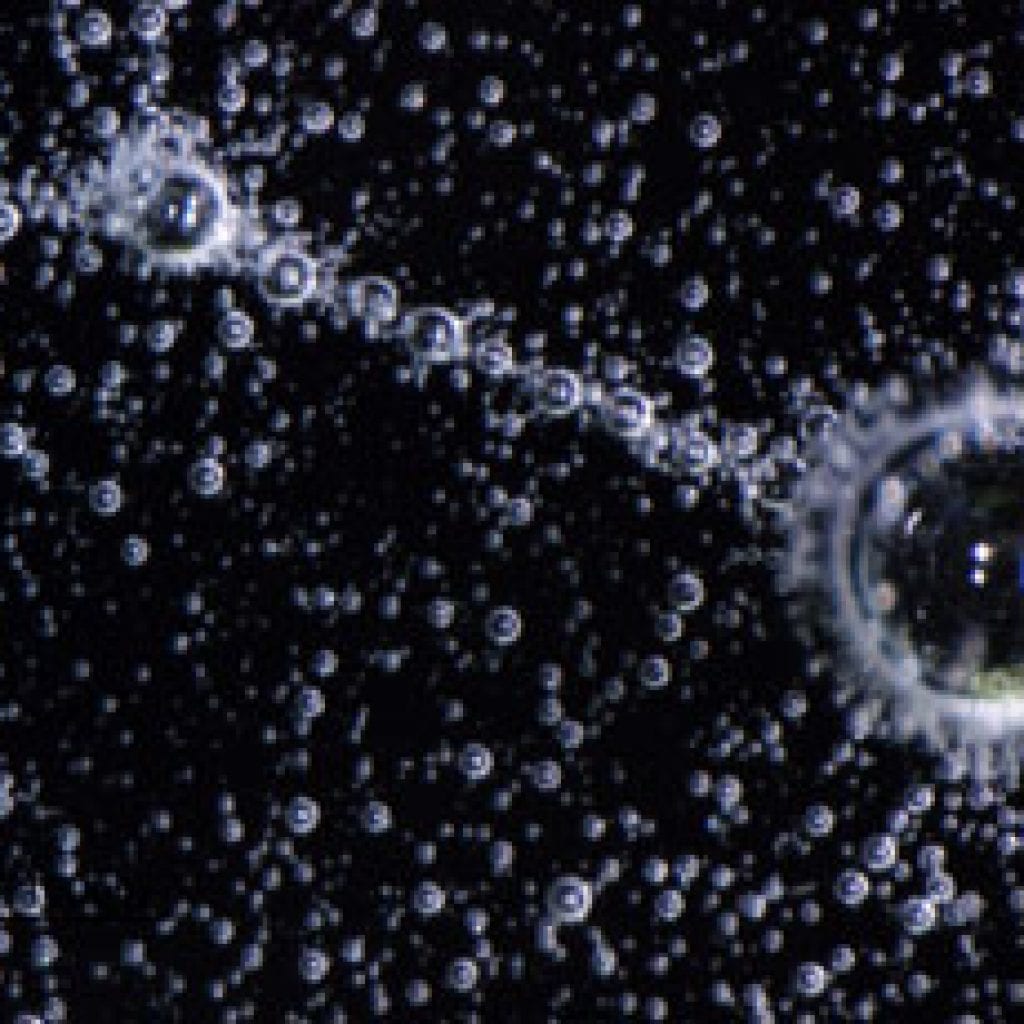

Bullseye clear and black (non iridized) blasted with 200 grit Silicon Carbide, and fired with the blasted sides facing one another. This micrograph is focused in between the layers. Note the huge number of trapped bubbles between the layers.

This is a close up of the above image.

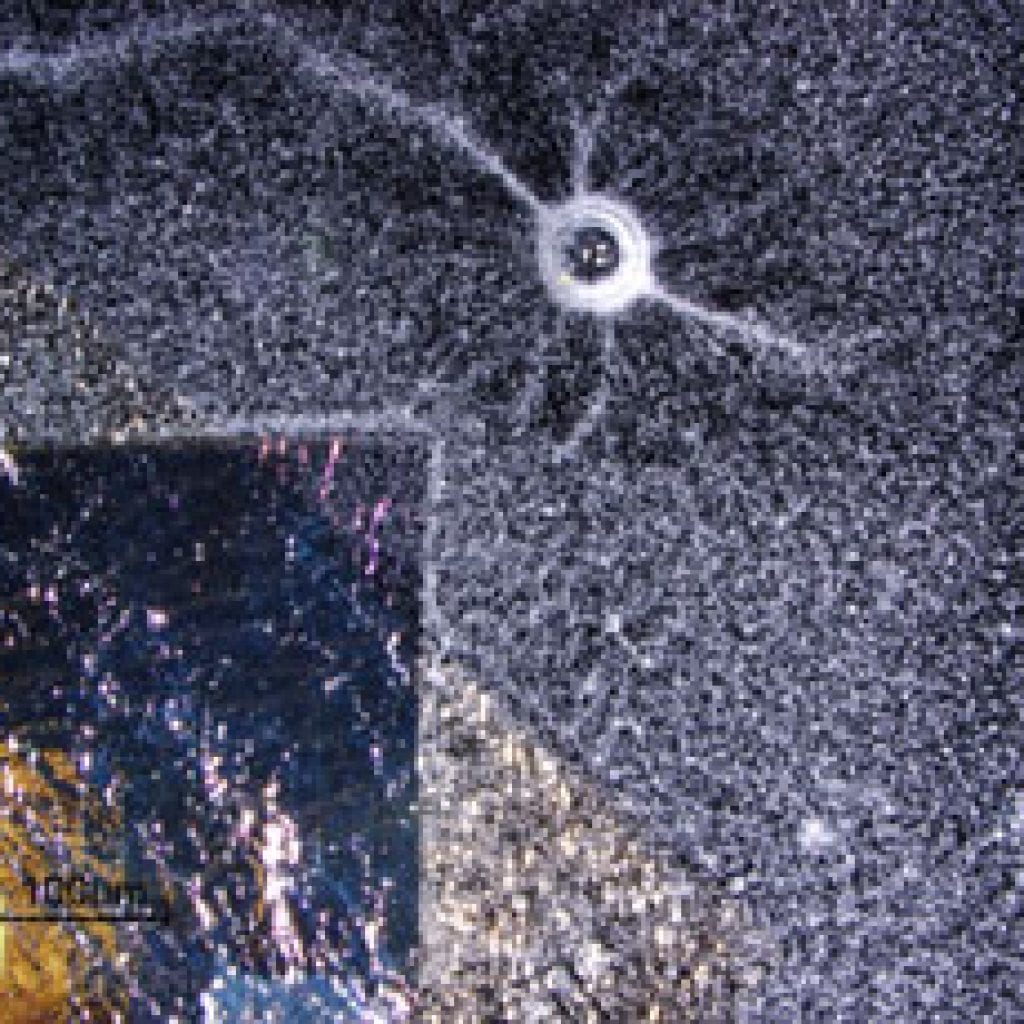

This sample has Bullseye iridized clear and iridized black. There is a design sandblasted with 220 grit Silicon Carbide on each irid surface and they were fired to 1490 degrees, with the irid sided facing. (The yellow frit was placed on this sample to help distinguish it from the others.)

Nikki notes: “Bubbles are trapped on all layers, and fewer are evident where only one layer was blasted.

Same sample as in the image above. This is a view of the corner, where both top and bottom surfaces were blasted toward the top and right. Only one surface blasted bottom and left. This demonstrates that the more blasting with SiC, the more bubbles.

If you are a kiln glass artist, and are interested in one of the best and most cost effective methods of learning both basic and advanced techniques, the Bullseye Kiln-glass Education Online video lessons are fantastic. Click on this link to see the free ones, and consider signing up for the rest.